Weekend Project: Nerf Dart Counter (Ammo Counter)

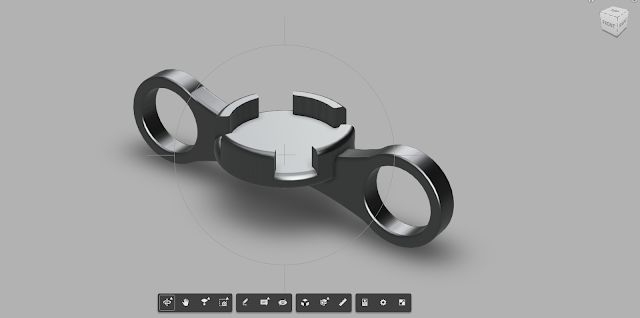

Recently I bought a Nerf Retaliator for my son on his birthday. I was scouting thingiverse for some accessories to print like Nerf Sight , then I came across AmmoCounter Mk1 Scope Case by Nathaniel Deal . Ammo counter lets you specify the magazine size and it will count down as you fire each shot. It will let you know how many bullets are left at any point of time. It is particularly useful for rapid fire guns and guns with 12, 18 or higher capacity magazines. AmmoCounter Mk1 Scope Case has a nice scope face which can accommodate two 7-segment displays, 2 push button switches and an on-off switch. It has a separate compartment for 9V battery, has openings to route the sensor wire and has removable tracks to put it on the tact rail. Over all a very well designed case. I was really impressed with the counter and decided to build one for my son. Dart Counter mounted on top of the Barrel extension A small video with Dart counter in action ...